| |

|

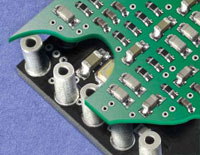

| Zierick’s Board Stacking Connector allows for more PCB design flexibility and more room for additional components. |

| |

|

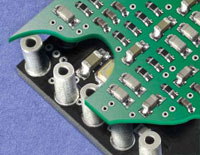

| The Board Stacking Connector joins the mother and daughter board with surface mount technology on both boards. |

| |

|

| |

Zierick has applied the benefits of

capillary action to our newest

interconnect product — the Board

Stacking Connector. This unique

connector surface mounts to both

the bottom and the top of a PCB,

allowing for the connection of a

mother and daughter board without

through-hole pins. The result? Greater PCB design flexibility,

more cost-efficiency and a higher

quality connection.

Available in bulk, on pallets or on

SMT tape, the Board Stacking

Connectors use minimal real estate,

allowing additional components to

be placed on the PCB. They are

self-centering and offer co-planarity

within 0.001", virtually eliminating

any alignment problems. Plus, they

have low contact resistance and a high

current rating to meet today’s modular

power requirements.

The Board Stacking Connector uses capillary action to provide superior

solder joint strength for a more reliable

connection. The connectors are first

surface-mounted to the mother board.

After reflow, the PCB with the

connectors are surface-mounted to the

daughter board.

Benefits

Zierick’s Board Stacking Connector:

Provides a cost-efficient board

stacking solution.

- Surface-mounts to the bottom

and top of a PCB for a stronger

mother board-daughter board

connection

- Uses existing placement machines;

no need for new insertion systems

Increases PCB design flexibility.

- Uses minimal real estate, allowing

for more components to be placed

on the PCB

- Eliminates the need for throughhole

pins

Allows for a better connection.

- Provides low contact resistance,

high current rating and

co-planarity within 0.001"

- Uses capillary action for a stronger

solder joint

|

|

Surface Mount

Surface Mount